Icon: enlarge

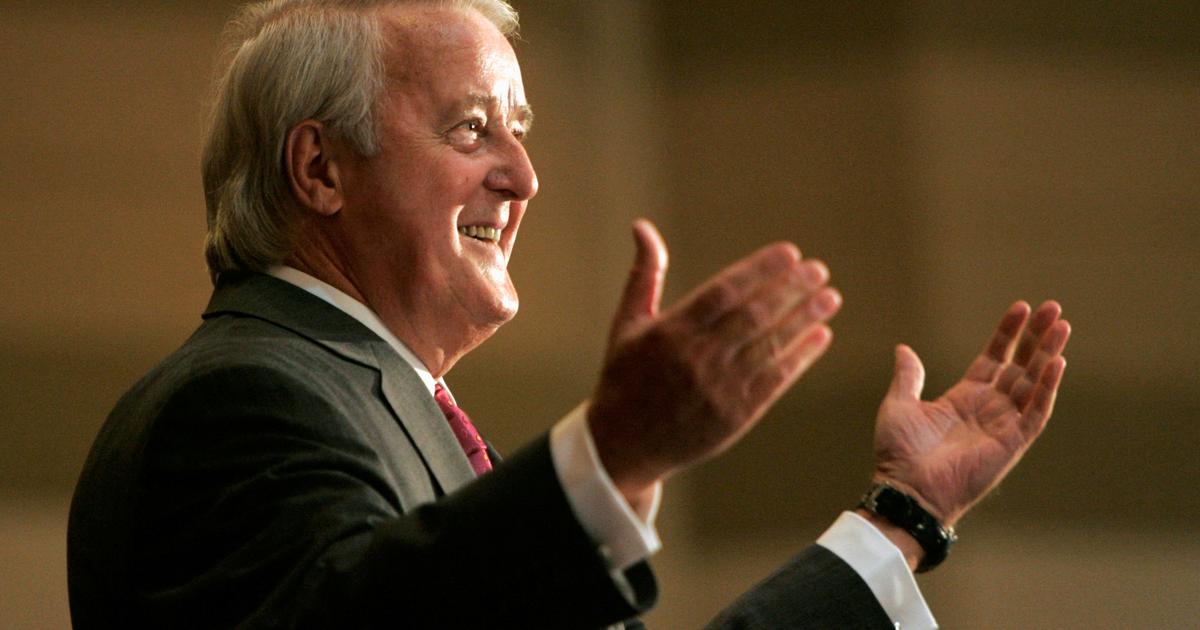

Mini-production in Oxford (archive picture): "We see friction at the border"

Photo: Geoff CADDICK / AFP

The British automotive industry is suffering massively from the coronavirus restrictions and Brexit.

Production fell by 29.3 percent compared to the previous year, as the industry association SMMT (Society of Motor Manufacturers and Traders) announced.

Around 920,000 vehicles rolled off the assembly line in the United Kingdom in 2020 - this is the lowest value since 1984.

The sharp decline is largely due to the global decrease in demand caused by the coronavirus pandemic, said SMMT boss Mike Hawes at an online press conference.

The British automotive industry is heavily dependent on export.

More than 80 percent of the cars manufactured in the country go abroad, over half of them to the EU.

Exports to EU member states plummeted by more than 30 percent.

Exports to the USA were similarly steep.

By contrast, more was exported to China, South Korea and Taiwan, the countries less affected by the pandemic than in the previous year.

Manufacturers are switching to air freight due to customs problems

Many factories were shut down for several weeks last spring.

Several manufacturers also extended their factory holidays to the turn of the year in order to cushion the difficulties caused by the changes in trade with the EU after the end of the Brexit transition phase.

But the Brexit, which was finally completed at the end of the year, also plays a considerable role for the business of British car manufacturers.

Hawes also contradicted British Prime Minister Boris Johnson, who had dismissed the problems at the borders with customs formalities and food safety controls as teething troubles.

“We see friction at the limit.

It doesn't bring production to a standstill, but it puts a lot of pressure on it, ”says Hawes.

Some manufacturers are dependent on deliveries by air freight to keep the assembly lines running.

The additional effort goes beyond teething problems.

"This is the new reality, the industry has to adapt to it."

What is positive about the trade and cooperation agreement concluded between Brussels and London is that a transition phase has been agreed for the rules of origin for electric vehicles and batteries.

This allows a gradual increase in capacities.

Overall, the industry wants to change towards hybrid and purely electric drives.

Now it is hoped that the end of the Brexit uncertainty will result in increased investments in Great Britain.

The announcement by Nissan to increase the production of batteries at its plant in Sunderland in northern England fits in with this.

Icon: The mirror

apr / dpa