01 Investigation

Written by: Li Yinglin

2020-05-09 12:38

Last update date: 2020-05-09 12:40The government spent 800 million yuan on research and development of reusable masks at the beginning of the year. Finally, Chief Executive Lin Zheng Yuee announced on Monday (4th) that he would distribute "copper core anti-epidemic masks" developed by the Hong Kong Textile and Apparel R & D Center. Xue Yongheng, Director of the Innovation and Technology Bureau, said that after 60 cleanings of the copper core mask filter element, its performance will only be slightly reduced.

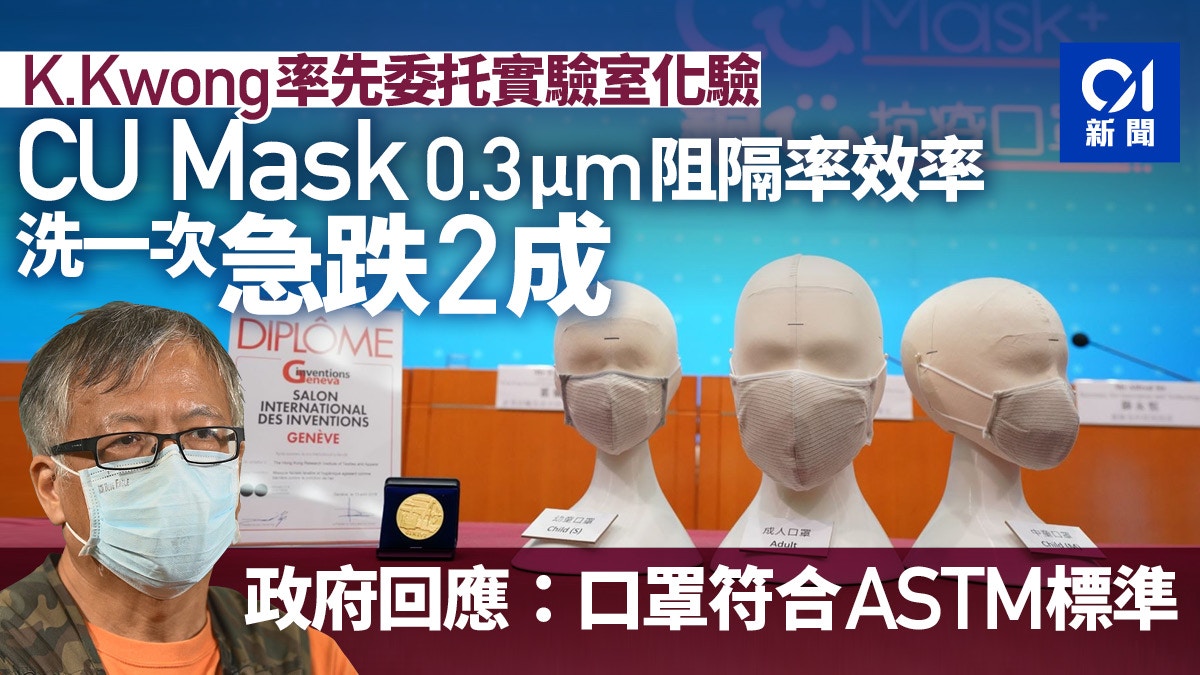

K Kwong, Ph.D. from the Department of Chemistry of the University of Hong Kong, commissioned a laboratory to conduct a preliminary 0.3㎛ filtration rate test on two copper-core masks. K Kwong found that after cleaning once, the filtering effect of the masks fell by 20%.

K Kwong cooperated with a local engineering company in February to develop a reusable mask "HK Mask" which had earlier criticized copper core masks for design flaws. The Innovation and Technology Bureau replied that the test results of Hong Kong's textile and apparel R & D clearly show that the mask meets the US ASTM F2100 first-class standard, saying that K Kwong's test was not conducted according to this standard. The reporter checked the information and the government's test did not include the 0.3㎛ filtration rate test. Infectious diseases specialist Zeng Qiyin pointed out that the test results may be related to the quality control of masks.

The "copper core anti-epidemic mask" developed by the Hong Kong Textile and Garment R & D Center has a 6-layer structure. The government claims that the mask meets ASTM F2100 level 1 in terms of particle filtration efficiency (PFE), bacterial filtration efficiency (BFE) and synthetic blood penetration resistance standard. (Profile picture / Photograph by Zeng Ziyang)

The "copper core anti-epidemic mask" developed by the Hong Kong Textile and Apparel R & D Center has a 6-layer structure, which is the first and last layers of cotton cloth, and 4 layers of filter elements. The government claims that the outer knitted fabric of the mask is made of copper oxide mixed cotton, and one of the filter elements also contains copper to prevent bacteria. It also refers to the mask in terms of particle filtration efficiency (PFE), bacterial filtration efficiency (BFE) and synthetic blood penetration resistance , In line with ASTM F2100 first-class standards.

The government says the effectiveness of 60 cleanings has begun to decline

The government uploaded three test reports on masks made by the Taiwan Institute of Textile Industry Comprehensive Research on the official website of "Copper Core Anti-epidemic Masks". The institute conducted 5 cleanings before cleaning, 40 cleanings, and 60 cleanings. After the masks were tested, including the ASTM F2100-2019 9.3 and ASTM F2299-2017 standards, a 0.1㎛ filtration rate test was made.

The report pointed out that the average PFE of the mask before cleaning was 95.87%. After washing 40 times, the average PFE of the mask fell slightly to 95.87%; and after washing 60 times, the average PFE also fell to 94.75%. The government reminds that after 60 cleanings, the effectiveness of the mask may begin to decrease, and the filter element needs to be replaced.

According to the test report uploaded by the government on the official website of "Copper Core Anti-epidemic Mask", under the (ASTM) F2100 first-level standard test, the average PFE of the mask after 60 washings is still 94.75%. (CU Mask webpage)

K Kwong, Ph.D., Department of Chemistry, University of Hong Kong, commissioned a laboratory to test two copper-core masks. According to K Kwong, the first and last layers of the four-layer filter element of the mask are non-woven fabrics, the middle two layers are melt-blown fabrics, and the non-woven fabrics are denser and light orange. He said that he had observed the light orange non-woven fabric with a microscope and found that there were copper fibers on the top: "Well, there are about 50 into the first." It is not clear from the experiment whether the copper on the mask is a common oxide or a nanostructure. But he added that if the human body inhales nano-copper, there is a chance that it may cause hydrops or fibrosis in the lungs.

The first layer and the last layer of the four-layer filter element of the mask are non-woven fabrics, the middle two layers are melt-sprayed fabrics, and orange non-woven fabrics with higher density and containing copper fibers. (Photo by Li Yinglin)

Two copper-core masks were tested. One was a mask that had been opened for about two days. It was worn, photographed, and cleaned by the reporter once, while the other was unopened. The laboratory conducted MPPS 0.3㎛ filtration rate test on two masks. K Kwong explained that 0.3㎛ size particles are more difficult to capture, and 3M N95 masks and HEPA filters commonly used in medical institutions also use this standard for testing.

The laboratory performed MPPS 0.3㎛ filtration rate test on the mask. (Provided by K Kwong)

K Kwong: The filtration rate dropped to about 75% after cleaning

The experimental results show that the filtration rate of the copper-core masks opened for two days is only about 73%, while the performance of the unopened masks is ideal, with a filtration rate of 96.5%. According to K Kwong, according to the government's guidelines, the masks with a filtration rate of 96.5% were washed with cold water and soap, and dried with cold air for about half an hour. The MPPS 0.3㎛ filtration rate test was conducted again. As a result, the filtration rate fell to about 75%. It fell by 20%, and the performance in the experiment was not as good as the government report.

K Kwong believes that the reuse of copper core masks has no epidemic prevention effect. "It is only needed once." It also means that the four-layer filter element is stitched with needle thread, which causes multiple pinholes in the filter element, and even air leakage will affect the filtration rate. He also pointed out that the filtration rate of the knitted fabric layer of the mask, the copper-containing non-woven fabric of the filter element and the dissolving spray cloth were tested separately. Reduce the filtering effect.

Regarding the test results, the Innovation and Technology Bureau replied that the Textile Industry Research Institute is an internationally recognized organization that can carry out ASTM F2100 standard verification. Therefore, the Hong Kong Textile and Apparel R & D Center commissioned the research institute to be a "copper core anti-epidemic mask + ™" authenticating. The test results clearly show that the "copper core anti-epidemic mask + ™" meets the American Society for Testing and Materials (ASTM) F2100 first-class standards. The spokesperson said that the tests commissioned by K Kwong did not appear to be in accordance with the ASTM F2100 standard.

Zeng Qiyin: or related to quality control

The infectious disease specialist Zeng Qiyin pointed out that if the 0.1㎛ filtration rate test result of the mask is more than 95%, it has reached the PFE requirements of ASTM Level 1, and it is considered that the use of 0.1㎛ filtration rate test is ideal: "The size of the new coronavirus It's about 0.1㎛, 0.3㎛ (test standard) will be a little bit worse. "He believes that copper core masks must be verified before they can get the relevant certification.

Infectious disease specialist Zeng Qiyin pointed out that the difference in test results may be related to the quality control of masks, and it is recommended to provide more masks to different institutions for testing. (Profile picture)

For the results of the MPPS 0.3㎛ filtration rate test made by K Kwong, Zeng Qiyin believed that it may be related to quality control. "I will not say that the masks are not up to standard. There is a chance that the quality of the masks that are certified for communication will be okay, but the quality will be different during the production, or K Kwong will get a defective mask." He suggested that more The masks were handed over to different institutions for testing to verify the quality of the masks, and whether the copper antibacterial technology mentioned by the government was effective against the new coronavirus.

CU Mask | Xue Yongheng: Pre-assure non-public bidding to decide the maximum support for 2.6 million citizens to register

CU Mask | Published by the media, the public manufacturer, the useless award-winning patent office pointed to the lack of sensitivity

CU Mask│Cai Shuxian ’s husband Mai Jingyu worked with Jingyuan CEO Science and Technology Bureau: Mai Wu recommended

Mask purchase guide ↓↓↓↓

+4

+3

+2

New Crown Pneumonia CU Mask Copper Core Anti-epidemic Mask