01 Investigation

Written by: Chen Runnan

2020-05-29 19:01

Last update date: 2020-05-29 19:12Although the "mask shortage" has passed, when the Hong Kong mask factory purchased the key upstream material "melt-blown non-woven fabric" for masks, it still faced the problem of sellers raising prices, detention by the mainland authorities, and even inferior fakes.

Local innovation companies aim at opportunities, develop and sell melt-blown fabric production machines, and teach local mask factories to produce melt-blown fabric technology to ensure the upstream material supply of the mask factory and improve the entire mask industry chain, Hong Kong will be a one-stop Production of masks.

The person in charge of the company, He Baoqi, said that the company has invested tens of millions of dollars in development so far. The initial production machine can only produce unqualified meltblown fabrics. Thanks to the experts of CityU, the two teams cooperated day and night to master the meltblown fabric production machine. The technology and principles can be used to teach other mask factories to the machine and technology. She also said that the company's staff and engineers are Hong Kong training local scientific research talents and have great confidence in the business.

"If Hong Kong manufacturers can master the technology of making meltblown fabrics themselves, and they already have good raw materials, they can ensure that the mask is the best mask." Wearing glasses, they talked cheerfully, and the tone was a bit like that of Taiwanese celebrity "Mrs. Science". He Baoqi is the chief executive officer of Pure Living, an innovative company. She said, "The key point is that Japanese masks are not qualified, but they don't have the best meltblown cloth!"

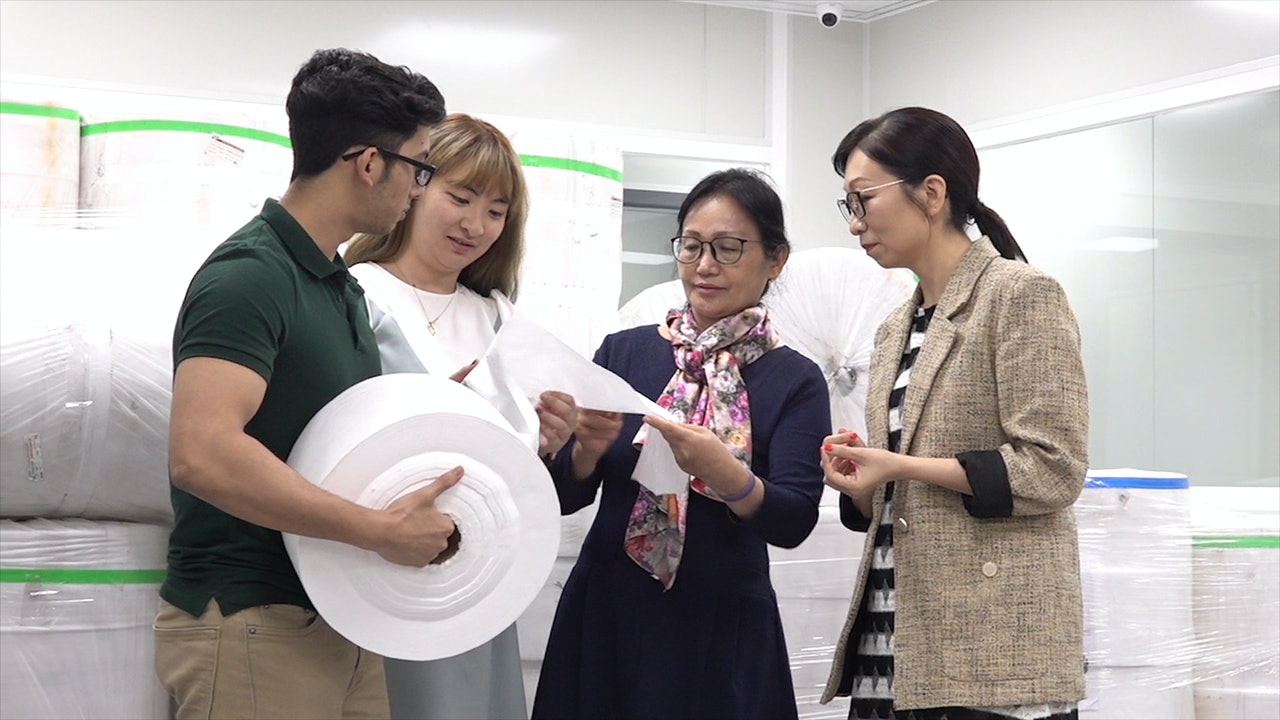

He Baoqi (right), who looks like a typical OL in Hong Kong, is very straightforward. He is the chief executive officer of Pure Living, a creative company. (Photo by Wang Haitu)

The key to solving the shortage of masks lies in the supply of "meltblown cloth"

He said that at the beginning of the epidemic, many business friends turned to her for help, in fact, they found a mask supply for their company. He initially focused on producing masks, but soon discovered that the key to solving the supply of masks was not the production of masks, but the more upstream material "melt-blown cloth".

The mask can play the filtering function, the key is that there is a thin melt-blown cloth in the mask. The meltblown cloth determines the filtering ability of the mask and the breathable comfort of the mask. Affected by the epidemic, the price of meltblown fabrics was 20 times that of 40,000 yuan, but the money did not guarantee the supply. "At that time, we inquired the powerful meltblown fabric factory, and the other party responded" You will try again next year. "He shared At that time, I thought that meltblown fabrics were unstable, and the mainland was detained again. Even if I bought them, I was not sure about the quality. I could never produce inferior masks. Why do n’t we produce meltblown fabrics in Hong Kong?

The picture shows the production process of melt-blown cloth. The so-called melt-blown nonwoven technology is to melt polypropylene chips (Polymer Chips) first, and then use air to spray the liquefied polypropylene into ultra-fine filaments. (Provided by the interviewee)

Mainland manufacturers sell second-hand "polishing" melt-blown cloth production machines

So the company started preparations in January. She originally planned to buy a melt-blown cloth production machine to make melt-blown cloth. However, she tried to send engineers to prepare the machine in China. After investigation, she found that the mainland manufacturers re-polished the equipment and used it. Equipment refurbishment is sold as first-hand equipment. It turned out that even melt-blown cloth production machines are "learning," reflecting on their company's chemical background and R & D team, they simply decided to develop melt-blown cloth production machines, selling machines and production technology to Hong Kong and overseas mask factories.

"Making a mask (difficulty) is one star, and melt-blown cloth is 9 stars." He said that at the beginning, the company purchased a melt-blown cloth production machine and placed it in the Shenzhen plant, and continued to study the components of the production machine, and Meltblown nonwoven technology. The so-called melt-blown non-woven technology is to melt polypropylene chips (Polymer Chips) first, then use air to spray the liquefied polypropylene into ultra-fine silk, and finally roll it into a cloth shape, the process is different from textile fabrics. "The cloth system is built, and the machine can run, but the block meltblown cloth is worn by the middle department." So she asked the university teacher for help. Professor Chen Guohua, currently the associate vice president of the Hong Kong Polytechnic University, Chen introduced her to meltblown. Hu Jinlian, an expert in weaving technology, teaches at City University.

Hu Jinlian ’s university research team assisted in mainly adjusting the parameters of the machine, the most important temperature after polypropylene liquefaction, and the indoor humidity and temperature have an impact. (Photo by Wang Haitu)

Local research backbone products have reached US European standards

Professor Hu Jinlian started to work as a company consultant in April. She recalled that the melt-blown cloth manufactured by Pure Living was "handicapped". The thickness of the melt-blown cloth for general masks is 1 to 5 microns, but the melt-blown cloth fiber The thickness is up to 30 microns. Afterwards, Hu ’s university research team assisted, mainly adjusting the parameters of the machine, the most important temperature of the polypropylene after liquefaction, and the indoor humidity and temperature all affected. They also studied the formula of polypropylene, and tried at least 4 kinds of materials. Hu is very confident to say: "At present, the products produced by the company have reached the European standards of the United States. It is still not comparable to the quality of Japan, and we still have to work harder to do better."

At present, the company's meltblown cloth production machine can produce meltblown cloth up to BPF99 specifications. Overcoming technical difficulties, all rely on a group of local scientific research talents. "I absolutely support local research and development. We already have a group of well-trained engineers." Pure Living's original main business was the patented technology independently developed to provide automated dispensing systems and high-tech production for university laboratories, pharmaceutical factories, laboratories, etc. Purification reagents are the key science and technology companies of the Science Park Science and Technology Entrepreneurship Training Program. He Baoqi also graduated from the Department of Chemical Engineering at the University of Science and Technology. She said that the company ’s research backbone is mostly graduated students and Ph.Ds from local universities such as the University of Science and Technology and the University of Hong Kong. Graduates are very capable! "

He Baoqi (middle) is also a graduate of the Department of Chemical Engineering at the University of Science and Technology. She said that the company ’s research backbones are graduates and PhDs from local universities. "My past experience shows that local graduates are very capable!"

Thousand-foot clean room can be assembled for future research and development

"We can provide 30 melt-blown cloth production equipment. It is estimated that after the market is successfully launched, it will reach a breakeven in 2 to 3 months." He said that the initial price of the melt-blown cloth production machine developed by their company was about 4 million yuan. It can produce 10 tons of meltblown cloth in a month, and the mask factory only needs about 1,000 feet of dust-free workshop to assemble. They will provide local technical support and supply of specially formulated polypropylene. Because the current price of meltblown fabrics is still high to 700,000 yuan per ton, and the supply is also unstable, He believes that meltblown fabric production machines have demand in Hong Kong and overseas, and they are confident that there are business opportunities.

"Wear masks are already a necessity. Consumers will choose branded and quality masks." He said "meltblown cloth is a technology that can not only be used as a mask. There are many protective clothing and medical applications that require better quality meltblown. Cloth. If there is income in the future, we can invest in universities and do more research and development. "

+10

+9

+8

New crown epidemic caused German "meltblown nonwoven" market to soar

[New Crown Pneumonia] Meltblown Nonwovens Global Out of Stock Professor: Hong Kong Conditional Production

[New Crown Pneumonia] Hong Kong homemade mask filter? Professor of CityU: The company has contacted me

New Coronary Pneumonia Mask Teaching and Market Innovation Board

/cloudfront-eu-central-1.images.arcpublishing.com/prisa/LEM52JP6LEADMSIBFMVD2O4ZO4.jpg)