While carmakers like Volkswagen and Daimler are scaling back their production and shutting down assembly lines, Tesla boss Elon Musk seems to see the global chip crisis easily.

Palo Alto, USA - The chip shortage has become a perennial problem in the auto industry.

Large car manufacturers such as Volkswagen, Daimler, Porsche and Co. have to send employees on short-time work and reduce production.

The reason: There is a lack of semiconductors.

Tesla is also facing the problem, but came up with a creative solution in August.

Now Tesla boss Elon Musk is speaking again on the subject - and contradicting other carmakers with his prognosis.

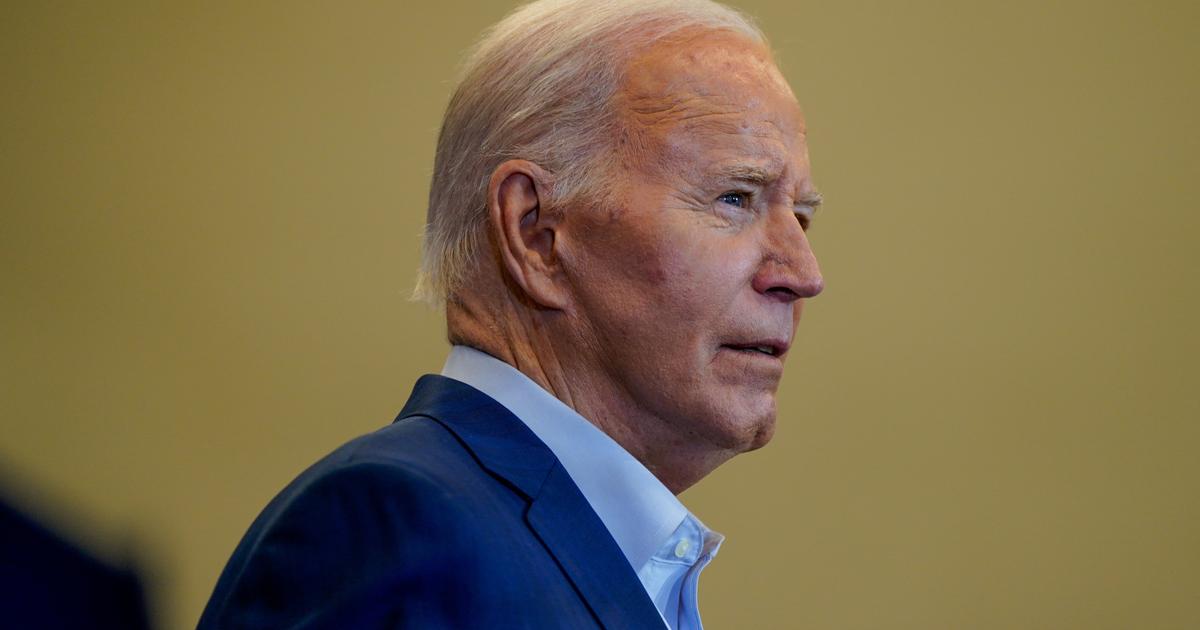

Tesla CEO Elon Musk: "Chip shortage is a short-term problem"

The crisis will last longer "than we all thought," said the analyst Dan Hearsch of the US consultancy Alix Partners of the

Bloomberg

news agency

.

The automaker's semiconductor stocks have now been used up: "The barrel is empty, there is nothing left to get," said Hearsch. At Volkswagen, it is assumed that the chip crisis will last until the end of 2022. That said, for example, Purchasing Director Murat Aksel. BMW boss Oliver Zipse noted at the IAA in Munich that the “fundamental tension in the supply chains will continue for the next six to twelve months”.

Tesla boss Elon Musk is more optimistic.

At the Italian Tech Week in Turin on Friday, he said that the global chip shortage in the auto industry was only "short-term in nature".

Many chip factories are currently being built, which is why there will be enough capacity next year.

"I definitely hope so, but it looks like it," continued Musk.

Tesla creates record production during chip crisis

It sounded different in August.

At that time, Musk had stated that Tesla was also affected by the chip crisis.

He had also railed against the chip manufacturers Reneseas and Bosch.

Still, Musk found a solution to the semiconductor shortage.

While the assembly lines were idle elsewhere, Tesla built more cars than ever before.

In the second quarter of 2021, the company posted net income of over $ 1 billion for the first time.

Tesla's secret recipe: The electric car manufacturer used alternative chips and rewrote the software.

Musk also seems to be safeguarding itself for the future: The

Teslarati

blog

reports that Samsung has chosen the Taylor site in Texas for a new semiconductor plant.

This is about 40 minutes from Tesla's gigafactory in Texas.

Semiconductor deficiency: How short-term is the semiconductor deficiency really?

The reason for the chip crisis in the auto industry is homemade: During the Corona crisis, the auto industry canceled large quantities of semiconductors.

The chip manufacturers continued to produce and found new customers, for example in the computer industry.

Because during the pandemic, the demand for computers, smartphones and tablets increased.

When the demand for cars picked up again, the chip manufacturers had already reoriented themselves.

The auto industry realized the dependency of its supply chains too late.

Other factors were raw material shortages and tensions between China and the USA.

According to estimates by the US consultancy Alix Partners, the shortage of chips is costing the industry US $ 210 billion. In total, 7.7 million fewer cars are produced due to the lack of materials. As recently as May, Alix Partners had spoken of a loss of 110 billion US dollars. The chip crisis is not only about billions in losses, but also about national security. Dependence on Asian producers could make sabotage or espionage possible, Asian chips in electrical appliances and cars would be like a Trojan horse. The US has therefore declared the shortage of chips to be a national security issue. Europe is also trying to become more independent from the Asian market through domestic plants and has the

Important Project of Common European Interest

program for this purpose

, Ipcei for short.

It is currently unclear whether there will be a quick solution to the delivery bottlenecks, as predicted by Elon Musk.

Over a thousand work steps are necessary to manufacture a chip, and the construction of a plant is also a lengthy process: the construction of the semiconductor plant in Villach, Austria, for example, took three years.

"We can slow down and shut down quickly in our industry, building new capacities takes a long time," Infineon boss Reinhard Ploss told

Spiegel

.