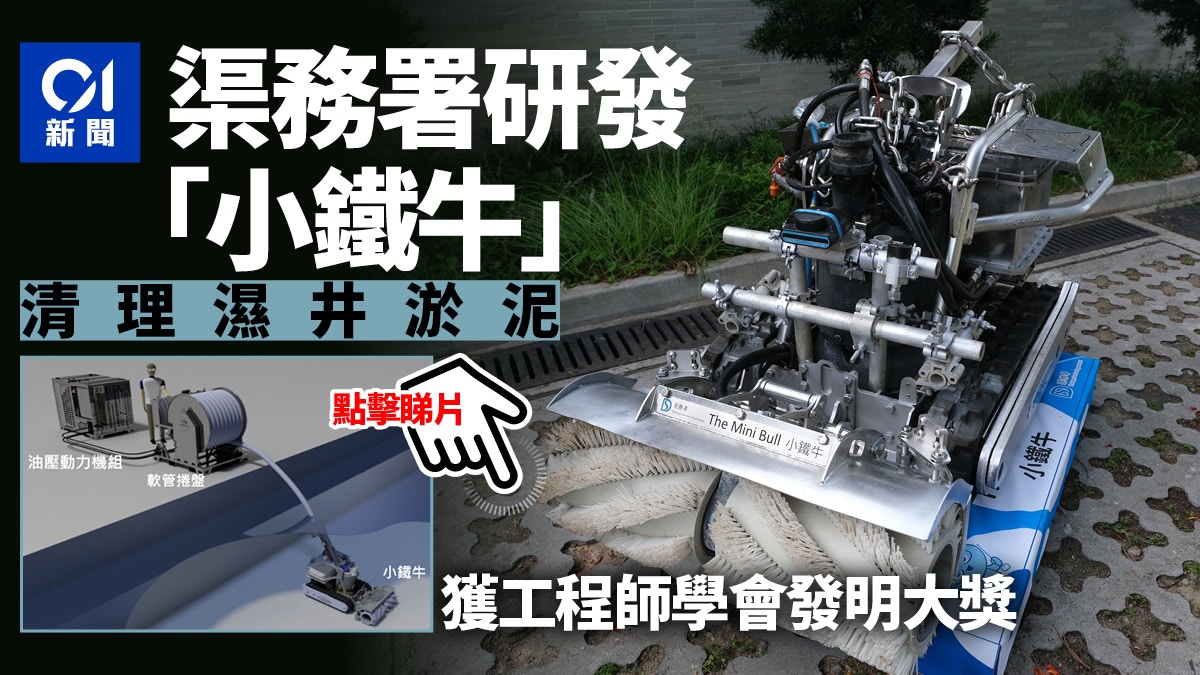

Wan Chai East Basic Sewage Treatment Works (Wan Tung Works) is one of the basic sewage treatment plants under the second phase of the Harbour Treatment Scheme. Considering the safety of workers working in wet wells and increasing the efficiency of dredging, the Drainage Services Department team last year Successfully developed an underwater vehicle with a cost of about 2.5 million yuan, which is aimed at dredging mud in wet wells - "Little Iron Bull".

"Little Iron Cow" is currently the first to be used in the Wandong Plant, and the Department will plan to expand its application to other similar sewage treatment facilities in the future to assist in the dredging work.

"Little Iron Bull" also won the Hong Kong Institution of Engineers Invention Award and the Silver Award at the 2022 Geneva International Exhibition of Inventions.

Last year, the Drainage Services Department team successfully developed a "Little Iron Bull", an underwater robotic vehicle with a cost of about 2.5 million yuan for the dredging of wet wells.

(Photo by Lu Yiming)

The sewage treatment capacity of Wan Chai East Sewage Works is 150,000 cubic meters per day (about 60 standard swimming pools), making it the largest sewage treatment facility and regional control center on Hong Kong Island.

After the collected sewage is screened to remove large solid waste, it will flow into the wet well, and then be pumped to other facilities in the plant for purification.

Since the impurities in the sewage are deposited at the bottom of the wet well over time, which affects the efficiency of the pumping equipment, it is necessary to regularly send personnel to carry out dredging work.

Workers must work in confined spaces and can only be dispatched in the early morning hours

Leung Wanting, an Electrical and Mechanical Engineer (Sewage Treatment) of the Drainage Services Department, said that the traditional well dredging work has safety risks. Workers have to work in a confined space and need to go out of the well to rest regularly. In addition, they need to avoid affecting the operation of the plant. In the early morning hours, related work can only be carried out, so the available time becomes less, the efficiency is relatively low, and the working environment is not ideal.

In order to ensure the safety of workers, increase the efficiency of dredging work and reduce the high maintenance cost, the DSD team successfully developed an underwater robot vehicle for wet well dredging work - "Little Iron Bull" last year, which replaces workers to enter wet wells to clean up sediment thing.

From design, assembly to field and non-field testing, the entire research and development process takes about 1.5 to 2 years.

"Little Iron Bull" won the Hong Kong Institution of Engineers Invention Award and the "2022 Geneva International Exhibition of Inventions" Silver Award.

(Photo by Lu Yiming)

The "Little Iron Bull" was put into operation at the end of last year. It weighs 800 kilograms, has a pump speed of 80 cubic meters per hour and a runner speed of 2000 rpm. It is equipped with crawler tracks to facilitate walking on uneven sediments. Designed in stainless steel to prevent corrosive sewage.

Leung Wanting said that the "Little Iron Bull" has several features. For example, the front of the car is equipped with rotating scallops, which can break up the sediment at the bottom of the wet well, and then pump it to the ground through the throat for screening treatment; the car is equipped with advanced sonar imaging It can locate and walk in the sewage environment with extremely low visibility. Workers only need to use a remote control and a tablet computer to instantly grasp the situation in the well and the position of the robot. She described this new method of dredging, especially Such as "playing machine".

In addition, the machine is driven by an independent hydraulic power unit, which reduces the immersion of live parts in water, and reduces the volume and weight of the body to increase safety and flexibility during operation.

The locomotive of "Little Iron Bull" is equipped with rotating shells, which can break up the sediment at the bottom of the wet well, and then pump it to the ground through the pipe for screening treatment.

(Provided by Drainage Services Department)

Leung Wanting pointed out that in the past, the time for manual dredging was measured in months, but now the use of robotic vehicles is measured in days, describing "the efficiency is greatly improved".

She took the example of cleaning a ton of sediment. It takes more than a month for a human hand, a few hours for a robot car, and no more than a day for all the processes combined.

She also said that in the past, workers needed to have "approved worker qualifications" for dredging, but now they do not need professional qualifications when they are carried out by robotic vehicles. Workers only need to watch the training clip, and they can complete the training within one day and then start working. .

Wan Chai East Basic Sewage Treatment Works is the highest capacity sewage treatment facility and regional control center on Hong Kong Island.

(Photo by Lu Yiming)

Leung Wanting, Electrical and Mechanical Engineer (Sewage Treatment) of the Drainage Services Department, said that the "Little Iron Bull" can ensure worker safety, increase the efficiency of dredging work and reduce high maintenance costs.

(Photo by Lu Yiming)

Liang Wanting also said that because many non-field tests have been carried out before use, and potential problems have been solved to ensure that there is no problem in performance before the official application, there are relatively few difficulties encountered, and there are no major challenges so far.

Moving to Central Apps in the future

"Little Iron Bull" has completely replaced manual dredging.

Leung Wanting said that the robot car has a long service life and can be used for an unlimited number of times, and the wear and tear of underwater work is not large. Coupled with the durable design, it is believed that a "little iron cow" may be used for decades.

She said that as long as the robotic vehicle meets the size of the wellhead, it can be used, and it is estimated that most of the sewage treatment plants in Hong Kong are suitable.

Therefore, the Department will plan to expand the application of "Little Iron Bull" in the future, including in clean water facilities, sedimentation tanks of other sewage treatment plants, and underwater treatment works.

The department also said that the next step will be to move the "little iron cow" to the Central Basic Sewage Treatment Works to assist in dredging.

The "Little Iron Bull" was independently developed, assembled, and assembled by the Drainage Services Department's team, with parts and related equipment, such as the stainless steel waterproof material for the body, the built-in sludge pump, and the hydraulic drive system. The total cost is about 2.5 million yuan.

Conceptual illustration of a wet well in a sewage treatment plant.

(Provided by Drainage Services Department)

Drainage Services Department installs sensors to monitor the water level 24 hours a day and quickly analyzes flooding risks at various locations and responds accordingly Drainage Services Department plans to build underground stormwater storage tank waterproofing material in Tsim Sha Tsuen Centennial Garden to be completed in 2027 Drainage Services Department builds 3.8 km of artificial river in Yuen Long for relief Flooding risk in the city centre Shatin cavern sewage treatment plant is expected to be commissioned in 2029 to develop detection equipment developed by the Drainage Services Department to reduce the risk of employee injury

/cloudfront-eu-central-1.images.arcpublishing.com/prisa/HXJJWNKRZ5D5NKZOZI3RD7WCMY.jpg)