Digitization is also becoming more and more common in agriculture.

Even if the technology is often expensive, it also offers savings potential in times of price explosions.

A visit to the Maiers in Niederding.

Niederding – compressed air cylinders open the small gate.

The cow that has been waiting patiently in front of it runs into a small box.

The gate closes again with a soft hiss.

Soon two rotating brushes are getting to the four teats on the udder, cleaning them while water is added from small nozzles.

The four suction cups dock immediately one after the other, camera-controlled they find the four suction points.

You can see the milk flowing in the transparent tubes.

The milking robot is in action at the Maier family on Herrnstrasse in Niederding.

The Office for Food, Agriculture and Forestry (AELF) invited to the appointment on the farm.

The topic: Digitization in agriculture.

If nothing comes, the four teats undock again, the gate in front of the cow opens and the cow returns to the pen.

She is one of 50 in the company.

The next cow is already waiting.

But first the milking equipment needs to be cleaned.

To do this, the unit with the four suction cups moves fully automatically to the dishwashing brushes, which are mounted elsewhere on the machine.

In the meantime, the computer catches the cow that is now in the stall – so to speak: “It was already there, that doesn’t count!” The front gate quickly opens again.

The cow has to go, make room for the next one, and now the procedure repeats itself.

+

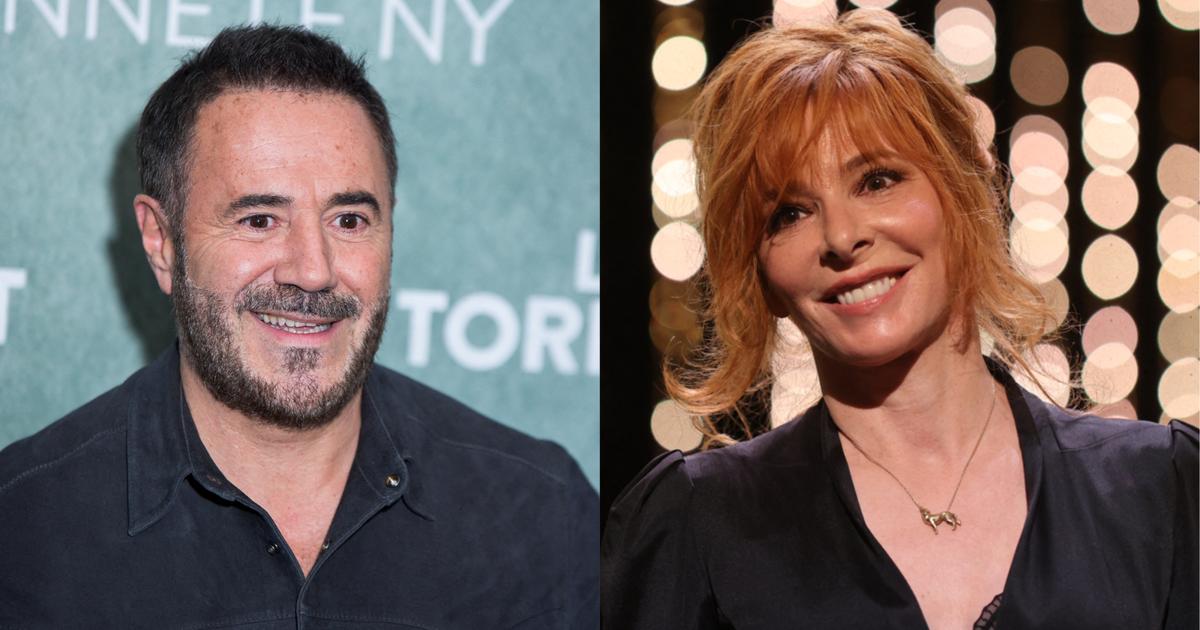

Dock please!

The milking robot in use on the farm of the Maier family in Niederding, another cow is already in the waiting position.

© Klaus Kuhn

Gone are the days when the farmer had to fight her way through her cows with the heavy milking can and then literally hunch over to get to the udder.

Digitization or automation is the order of the day.

And especially in times of skyrocketing costs for agriculture, this is a great opportunity.

Anton Maier's cows wear collars.

These are transponders, devices that are constantly connected to the main computer and tell it how the cow is doing.

It is important to Anton Maier's son Florian (24) that he always knows exactly what is going on in the herd.

“The device measures how long a cow chews the cud.

If this time is too short, this is a possible sign that she is not eating enough.

Then you have to check.” If a cow has a fever, a temperature sensor detects it and immediately sounds an alarm.

Animal welfare is the buzzword.

Today, a farmer has to invest 140,000 to 160,000 euros for such a system.

In the long run, this also pays off with corresponding stocks.

"We already have the second milking robot," reports Florian Maier.

A bit of farm romance remains: "All our cows have names here."

The weed control is completely unromantic: "Camera-supported hoeing technology" is the latest craze: robots that drive completely autonomously and GPS-controlled over the field and remove the weeds, but leave the crops where they are.

Meanwhile, the farmer can do something else: fertilize, for example.

The working width of a modern fertilizer spreader is 21 meters.

There are already some with 52 meters.

But what if a field tapers to a point?

The so-called spreading disc then rotates more slowly, while the flow of fertilizer decreases synchronously at the same time, and the working width is reduced, but the use per square meter is kept constant.

The computer has stored the shape of the field, GPS tells the computer where the tractor with the spreader is.

But there is more: Florian Maier talks about the latest generation of combine harvesters, which detect where the threshing yield is not optimal and automatically transmit this data to the computer on the farm.

He can then control the fertilizer spreader again.

It then fully automatically recognizes the area of the large field where more fertilizer may be required.

The Maiers' modern Fendt 722 Vario can be controlled with a joystick, data can be read on a monitor.

The GPS control prevents the pesticides, which are outrageously expensive, especially now because of the war in Ukraine, from going to the same spot twice.

The so-called application rate decreases.

Companies often use the modern machines together - a thing that is becoming more and more common.

One person who knows this is Josef Schächtl, a consultant at the AELF.

He thinks that's a good thing too.

"A ten-year-old machine is now totally obsolete," he says.

The AELF tries to publicize the topic through press events like the Maiers did.