The Public Works Laboratory under the Geotechnical Engineering Office provides a variety of construction material testing services for government projects. Currently, it conducts 600,000 tests for government public projects every year. Facing the increase in the number of projects, the Public Works Laboratory has developed the world's first "automatic concrete transfer test System" and the first "Automatic Rebar Testing System" in Hong Kong.

Zhang Weiwen, director of the Geotechnical Engineering Office, said that the introduction of two systems will help ensure the occupational safety of employees and increase the amount of testing.

Traditional concrete brick testing requires manual measurement of size and weight, and then placing the concrete brick in a curing water tank.

After the specified day, the staff took the concrete bricks out of the maintenance water tank, put them into the brick press for compression testing, and then visually judged whether the cracking mode of the concrete bricks met the standard.

The entire process needs to be handled manually, and there are risks of recording errors and accidents during manual operations.

The introduction of the "Automatic Concrete Brick Testing System" allows the use of computers to control the entire testing process, from measurement to using artificial intelligence to judge the cracking mode of concrete bricks.

The staff pointed out that the manual testing can test 100 bricks in 8 hours a day, and requires 2 to 3 employees to complete the whole process. The "automatic concrete brick testing system" can test 160 bricks in 8 hours a day. Only one staff member is required.

Zhang Weiwen said that the system cost about 9.7 million yuan to build, and the annual maintenance cost is about 500,000 yuan. At present, about 20% of the concrete bricks are tested with the system. In the future, the system is expected to be expanded so that 50% of the concrete bricks are tested with the system.

Traditional steel bar testing requires manual measurement of the length and weight of the steel bar, and drawing equidistant scales on the steel bar sample, and then putting the steel bar into the tensile testing machine. During the process, the staff needs to remove the extensometer to prevent the extensometer from breaking when the steel bar breaks. Damaged, the process has a certain degree of danger.

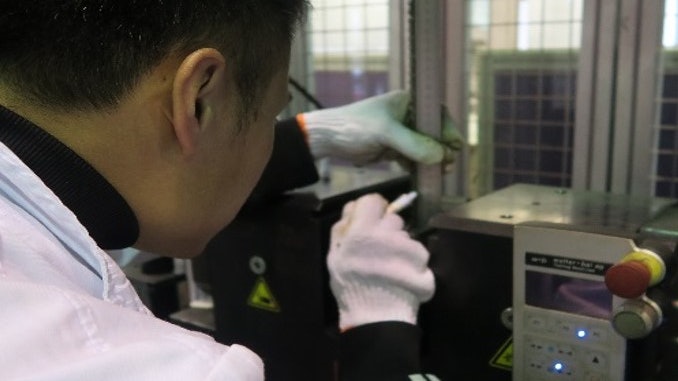

The introduction of the "Automatic Reinforcement Testing System" can use the mechanical arm to extract the required reinforcement from the sample rack for measurement, and then put it into the tensile testing machine. The staff can see the entire testing process and related data from the outside, reducing the time for manual input into the computer risk of error and injury.

The machine can test 80 steel bars a day, which is more efficient than manpower testing 50 bars a day.

Cheung Wai-man described the two automated testing systems as worthwhile, and the efficiency and quality of testing services will be improved.

(Photo by Deng Yushi)

Zhang Weiwen described the development of two sets of automatic testing systems as worthwhile, and the efficiency and quality of testing services will be improved. In the future, more manpower can be allocated to optimize services and continue to develop automated testing systems for other building materials.

6.18 rain disasters killed 138 people half a century ago Geotechnical Engineering Office organized a 50th anniversary retrospective exhibition to call for peace of mind Black rain caused 27 landslips Geotechnical Engineering Office drone survey and laser scanning survey Geotechnical Engineering Office predicts that extreme weather will become more common and will study Landslip Early Warning Measures The Geotechnical Engineering Office visited more than 60 secondary schools this year to promote slope safety and landslip knowledge