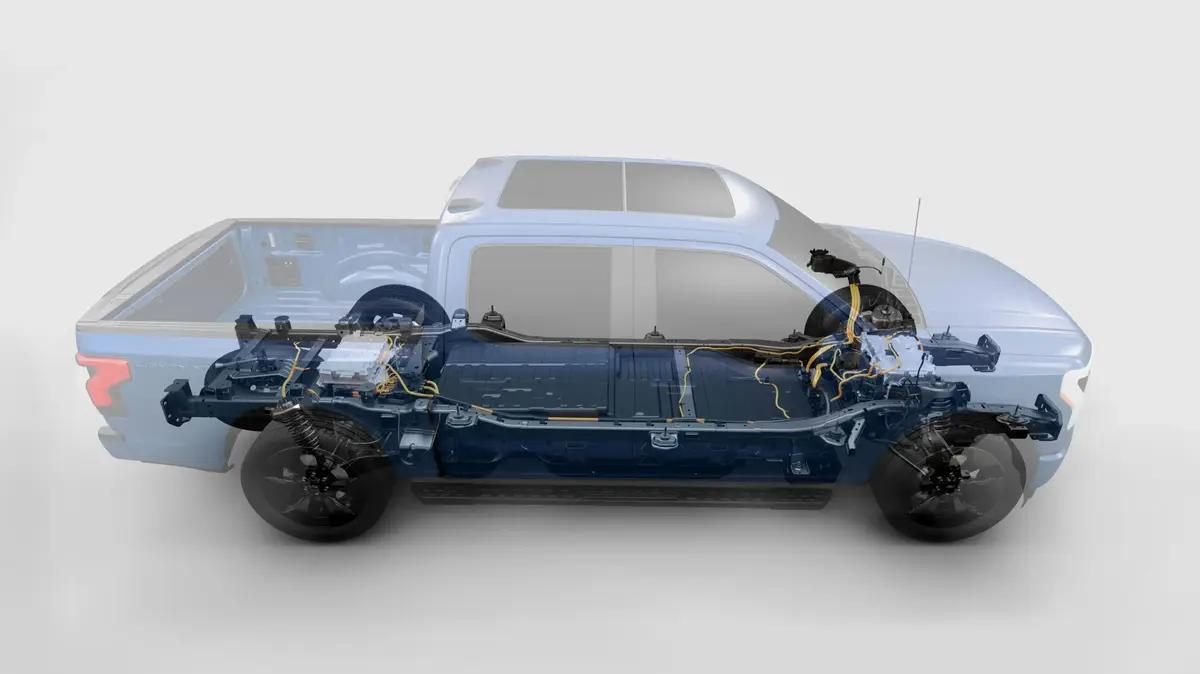

Ford F-150 electric.

Moving to large-scale production requires independence (photo: manufacturer's website)

After parting with its passenger cars in the United States and ceasing production of the Fiesta in Europe, Ford outlines the direction the company will take in the coming years - more crossovers and more electricity in its offer.

Now it is announcing another step in its overall move towards this goal - the construction of a large factory for electric vehicle batteries to be built in Michigan.

This is an unusual step since currently the vast majority of manufacturers purchase their batteries, like many other components, from external suppliers.

In order to establish the factory, it is partnering with the giant Chinese battery supplier CATL, which for its part is happy to set foot in the new continent, which is new for it.

Ted Miller, director of Ford's research center presents the LFP battery (photo: manufacturer's website)

Probably in order to avoid the sensitivities of Chinese ownership of production sites in the United States, and certainly in light of the current tensions between China and the United States over the downing of the Chinese spy balloon, the activities of the two companies will not be done through a normal partnership.

The plant will be wholly owned by Ford through its subsidiary.

For this purpose, Ford will actually produce the batteries under license from CATL, including an emphasis on technical expertise regarding the type of batteries that will be produced there using LFP technology.

The LFP batteries, acronyms for lithium iron phosphate, that the factory produced have so far been imported from outside the United States, which created not only a dependence on supply and the willingness to supply them, but also a lack of flexibility to deal with inventory problems or prioritization by the battery manufacturers themselves, which does not always work in favor of the manufacturers.

More in Walla!

The smart test that detects an increased risk of having a stroke - now on sale

Served on behalf of Shachel

The LFP batteries (on the right) take up more space, but are cheaper to manufacture (photo: manufacturer's website)

The company's chairman, Bill Ford, said that the local production will have another advantage beyond availability, when he noted that this may also be the key to lowering the costs of the batteries and, as a result, of the vehicles themselves. Since these batteries are cheaper than the common NCM or nickel cobalt manganese batteries More than today. According to Ford, they will be among the cheapest to manufacture.

The plant, which is expected to open in 2026 and cost, according to the company, $3.5 billion, is expected to employ 2,500 people. According to the company's announcement, it will be able to support the production of batteries in the amount of 400,000 vehicles per year. The batteries are intended for models such as the Mach E, The electric version of the F-150 and other future models of the manufacturer for the American market.

vehicle

car news

Tags

Ford

electrical power

electric car

electric car